Why Choose Us?

So many reasons, where should we begin? But if you’ve never tried us before, here’s a brief look at what makes us stand out.

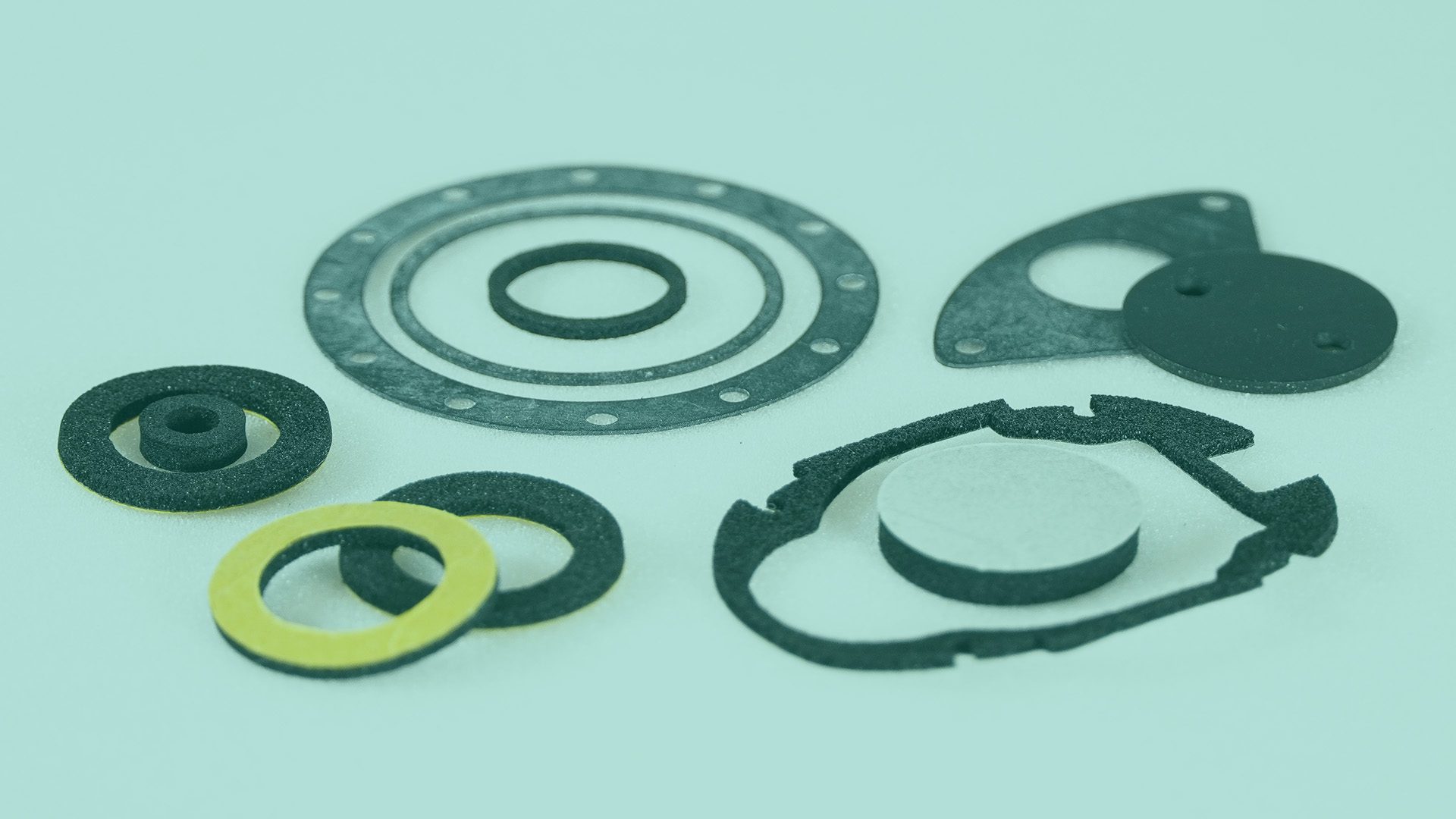

The need for seals & gaskets

Sealing your products is the best way to ensure its protection and safety. Get airtight and watertight sealing solutions for all your complex assemblies with Foam Conversion’s seals and gaskets. There’s no reason for you to worry about water, oil, heat, or dust anymore.

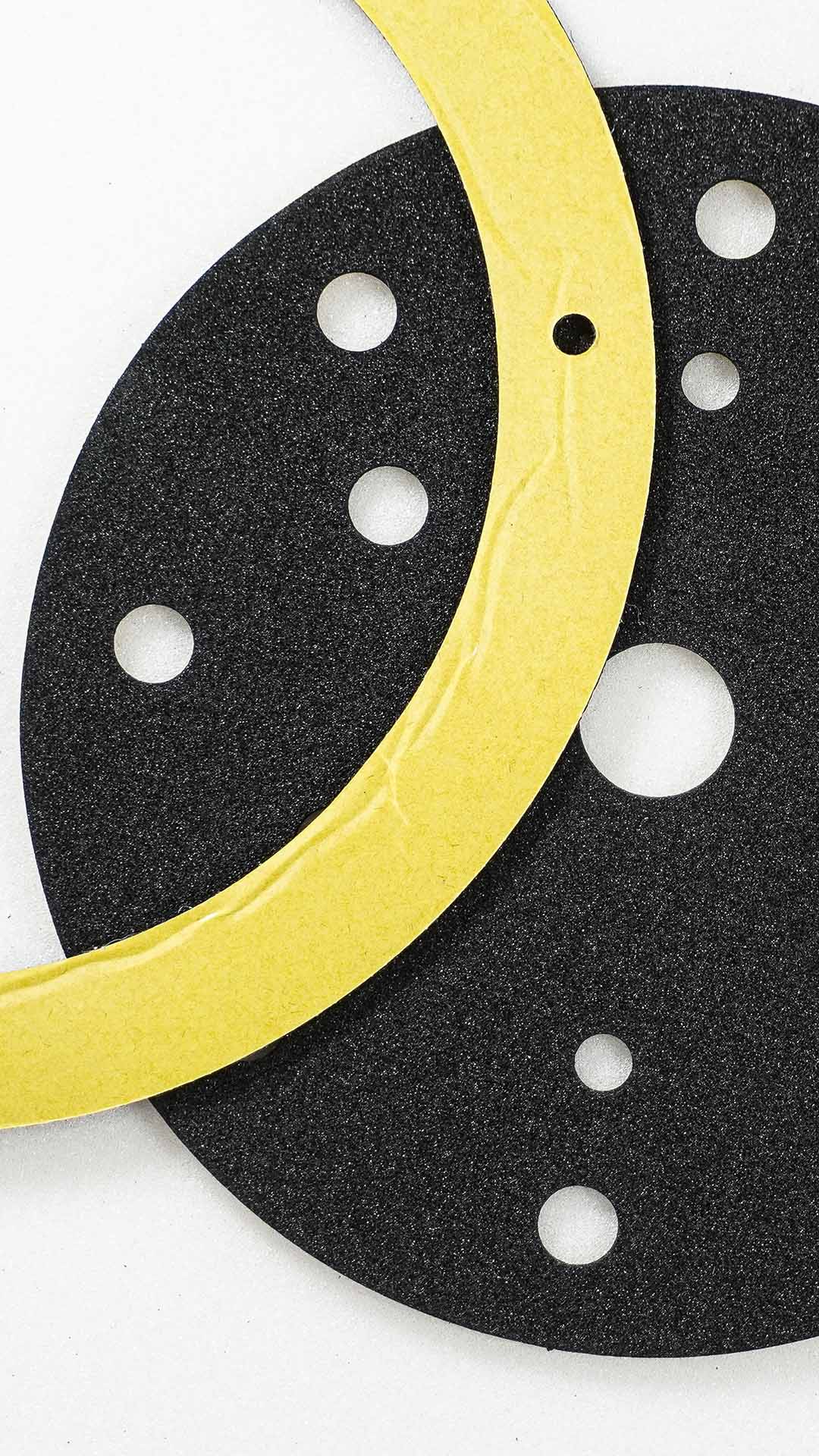

Used in a variety of sectors like automotive, electronics, and construction, we offer special sealing equipment. Fine-pored and made with modern materials like polyurethane and polyethylene, our foam varieties are available in blocks, sheets, and converted parts.

Self-adhesive backings

With excellent ageing resistance and dust preventing surface, our foam seal strips are manufactured after considering each of the essential factors. It is waterproof, windproof, and extremely easy to install, which means you could just DIY it. Here’s a plus point – some foam seals freeze and crack; ours aren’t one of them.

We also have available, the most adequate adhesive backings, which can be widely used for assembling interior setups, construction activities, and foam engineering.

What should you look for?

The main consideration when selecting gaskets and sealing foams is its resistance towards various damaging elements. Water, oil, fire, gases, and dust particles that could easily infiltrate your products are the reason you require quality sealing materials.

Foam Conversion’s sealing foams are made with the latest advancements and highly quality foaming materials. Other than the benefits we’ve already mentioned, our sealing foams are durable and easy to compress.

Trying Temperature

We’ve supplied quality seals and gaskets for application in extremely hot or cold environments. A wide range of sealing materials and gaskets that operate at high temperatures are available. These products are perfect for applications, including flame, exhaust, and elevated temperature.

We also offer excellent sponge rubber materials suitable for high temperature. Silicon, EPDM, Conductive Silicon, or Fibreglass, we’ve got it all covered for you.

Fire retardent solutions

Fire hazard is a major industrial issue, particularly when the products in use are not completely fire retardant. But to save all that hazard, Foam Conversion’s seals and gaskets are self-extinguishing, meeting significant international standards, and super long-lasting due to their high material resistance and stability.

In short, we not only deter fire accidents, but we also do it for a long time.

Materials

Products

Try our seals and we’ll make sure you stick with us

Our products are of the highest quality and lovingly created for you by our fully trained team, in the UK.

We contacted Foam Conversion to find a more suitable material for an existing component, they ended up helping us to completely review the design resulting in a superior product that could be retro-fitted into all of our enclosures.

UK Manufacturer of cooler systems