Our Services

Modern Materials

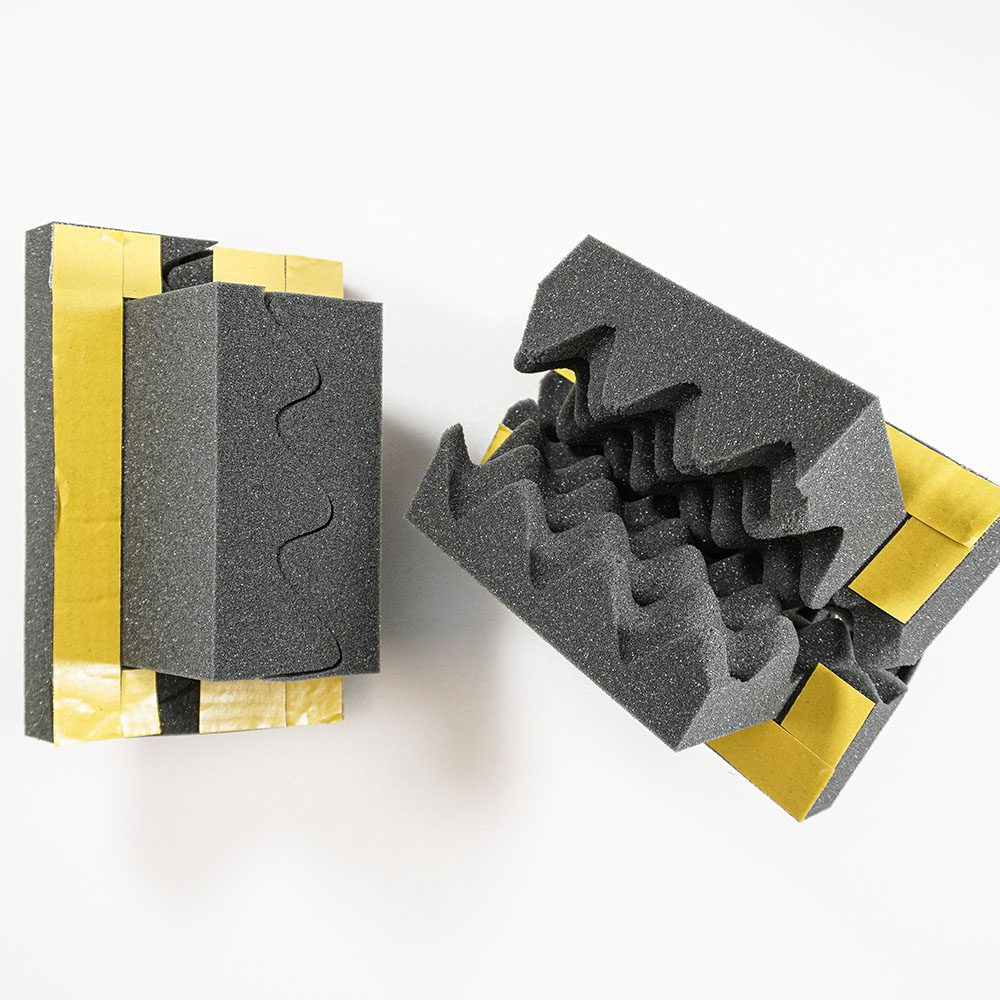

Wondering whether we’re up to date with foaming research? Let us tell you – we lead it. It’s among our top priorities to make sure that we use modern materials for all our products – dust-proof, fire-proof, water-proof, reticulated, soundproof – we have it all.

Experience

We’ve been converting foams for over thirty years, there is hardly a foaming problem we haven’t yet encountered. If you’re wondering whether your requirements are too much or too little, choosing an expert in the field would be a good idea.

Eco-friendly Foams

At Foam Conversion, the environment is super important. We believe in converting non-toxic, CFC free foams perfect for you and your business.

The Future

Our story

Like every other business, we have a dream. For more than 30 years Foam Conversion has given nothing but the best products and materials to its clients. Probably the reason why we’re still in business! With time, we’ve adapted to new technologies and requirements, never once staying static in our approach.

Our goals

We have always had a clear goal, to provide our customers with high quality products made from the best materials on the market, using the knowledge we have gained together with our engineering expertise to offer a comprehensive service tailored to meet your specific demands.

Want to know more about us and how we can help you?