Why Choose Us?

There is no substitute for experience. Having been the UK’s leading manufacturer of professional audio foams for more than 30 years we have gained a wealth of valuable knowledge. Trusted by some of the worlds leading manufacturers you can have peace of mind that we put all of this expertise into every product we make.

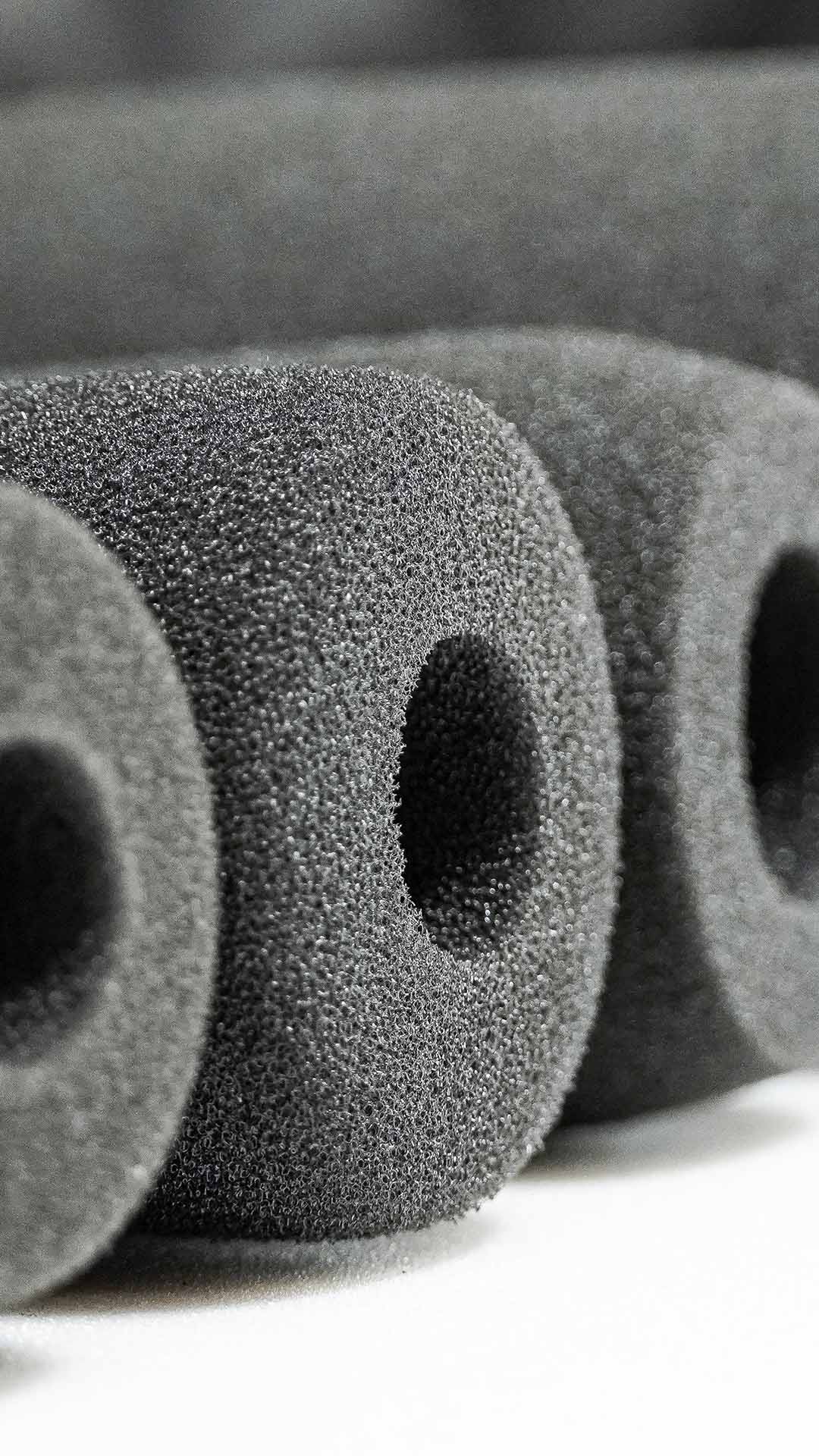

Have A Look At Our Range Of Polyurethane Foams

The diversity of polyurethane foams available in the market means it plays several vital roles within the manufacturing process of professional audio equipment.

Important for reducing wind interference and vibration to cancelling out unwanted background noises, choosing the right material is extremely important for the growth of your business and the peace of your mind.

Opening Closed Walls For Your Business

The Reticulated polyester foams are made to extremely high tolerances, resulting in a completely open cell, acoustically transparent material.

With diverse PPIs, these foams can be made suitable for a wide variety of uses by perfectly tailoring them to work on different microphones and audio capture devices. This helps in eliminating unwanted background noises, speech ‘pops’ and prevents dirt and moisture from entering the microphone.

We Don’t Stop Here

Once you have chosen your material and product, we can further enhance the audio foam’s natural qualities by several unique post-treatments.

These include a water-resistant impregnation which is now widely used on noise-monitoring windshields. These windshields have been left outdoors for long and need an anti-static coating which is used on military headsets.

The open cell acoustic foams are commonly used in headsets and helmets to eliminate unwanted noise and vibrations within the earpiece. We also stock a selection of specialist speaker cloths that can be used together with the foam to produce complex assemblies that ensure a clear, quality transmission of audio.

Promote Your Brand A Little Differently

If you’re looking for high-quality mic mufflers and printed windshields, Foam Conversion is all set to host you. While our quality products speak for ourselves, let us add the simple fact that we’ve been doing this for decades.

We realize how important non-intrusive promotional methods are and how to make them look simple, stunning and stylish.

Any shape or colour you bring to us, we promise we’ll recreate the perfect audio foam you have in your mind. With over 20 distributors globally and shipping to 100 countries annually, we are equipped to handle any challenge thrown our way.

Our Skills And Knowledge

Over the last 30 years, we have launched a range of bespoke machinery capable of producing extremely complex foam products to the highest quality standards. With a focus on design and research, we continue to work closely with our customers and help them in finding the best solution for their audio foam needs.

Since we’ve always tried to provide a complete solution to our customer’s needs, converting foams isn’t all that we do now. We’ve taken our business a little further and we now have full on-site lamination, flocking and printing facilities.

Materials

To get the most out of your personalized foam, choose one (or multiple) material mediums for your use. From reticulated foams to Grill cloth, we have it all covered. As of now, we provide our products in five different material mediums.

Products

Currently, our audio foams are available in six different varieties, each suitable for a different sort of application.

- Microphone Windshields

- Headset Foams

- Foam Dampers

- Ear Defender Foams

- Speaker Grill Foams

- Foam Padding

Gallery

Mic-mufflers for cool marketing

Customised audio foams are our forte. Enriched with several post-treatments like fire-retardancy and water-proofing, the final product will blow you away.

For innovative brand promotion, try our mic-mufflers, they’re made with utmost precision and available in various colours and sizes. Reach out to us via our form to know more!

Mark Bibby

Director